Cellular HVAC Monitoring Device

Overview

Designed and deployed a cellular IoT monitoring device for commercial HVAC systems, owning hardware, firmware, cloud ingestion, analytics, and user-facing platforms end-to-end.

Problem

Commercial facilities lacked continuous, remote visibility into Direct Expansion (DX) HVAC performance. Diagnostics required on-site visits, manual measurements, and reactive maintenance, leading to inefficiency, downtime, and higher operational costs. Existing solutions were either too expensive, too complex to install, or insufficiently accurate for real-world HVAC diagnostics.

Constraints

- Solo engineer responsible for the entire system

- Large number of analog signals (15–16 per device)

- Mixed-signal PCB design (analog + digital)

- Field installation by technicians, not engineers

- Cellular connectivity and power reliability

- Production readiness and manufacturability

- Tight timelines driven by enterprise customers

Solution

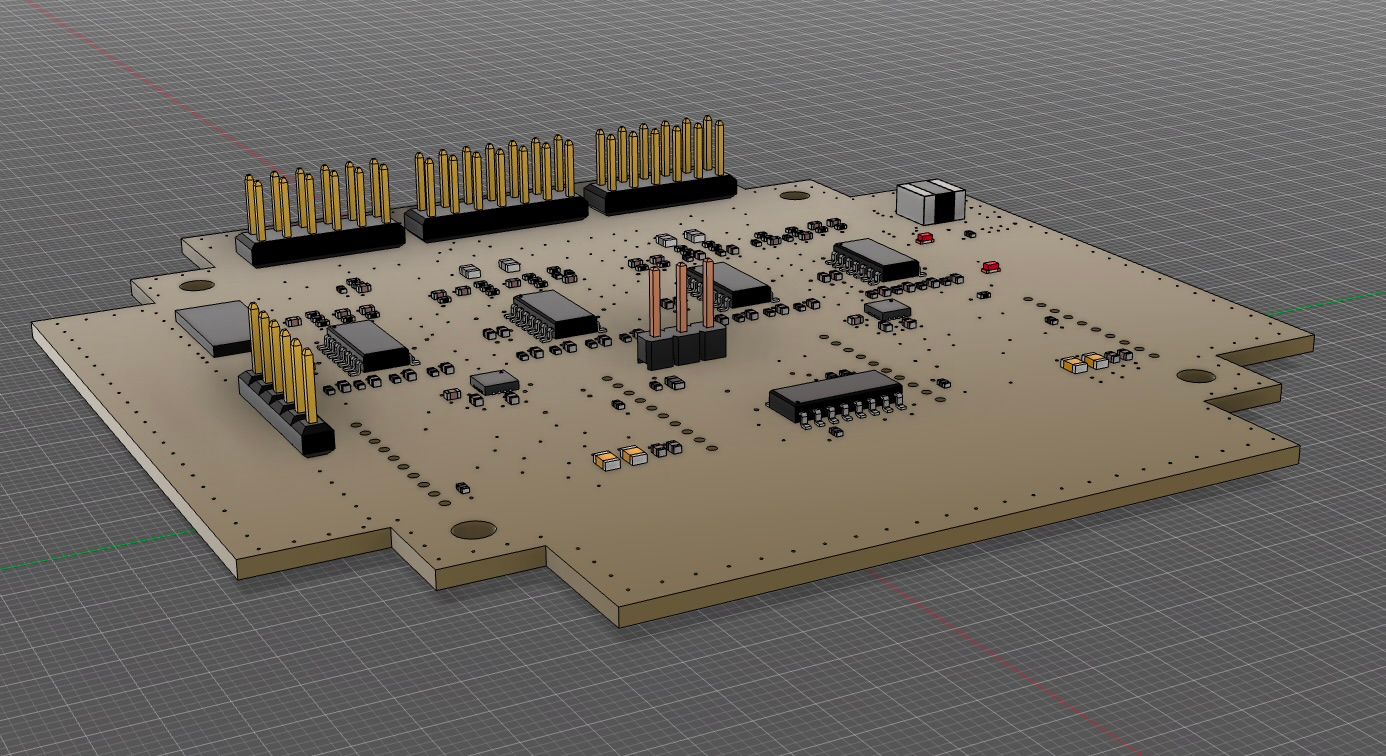

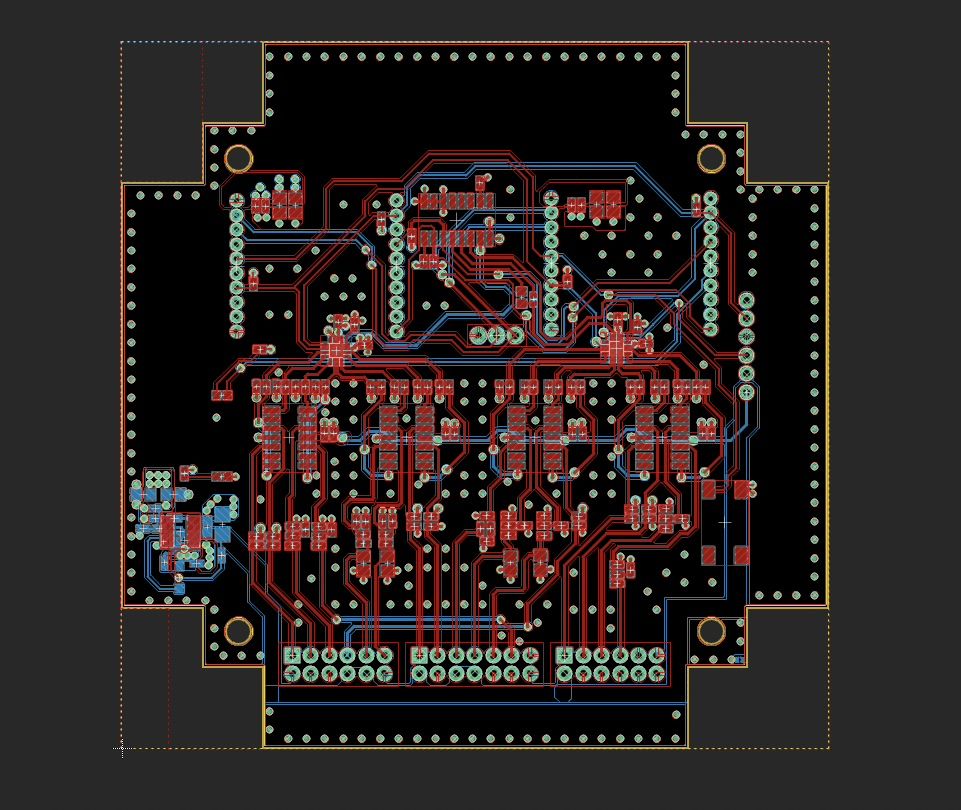

I designed a cellular HVAC monitoring device from scratch, covering the complete product lifecycle. This included an analog front-end supporting 4–20 mA pressure transducers, 10 kΩ thermistors, and 0–5 V CT/voltage sensors. I used an I²C-based ADC architecture with careful mixed-signal routing and designed the custom PCB in Eagle CAD.

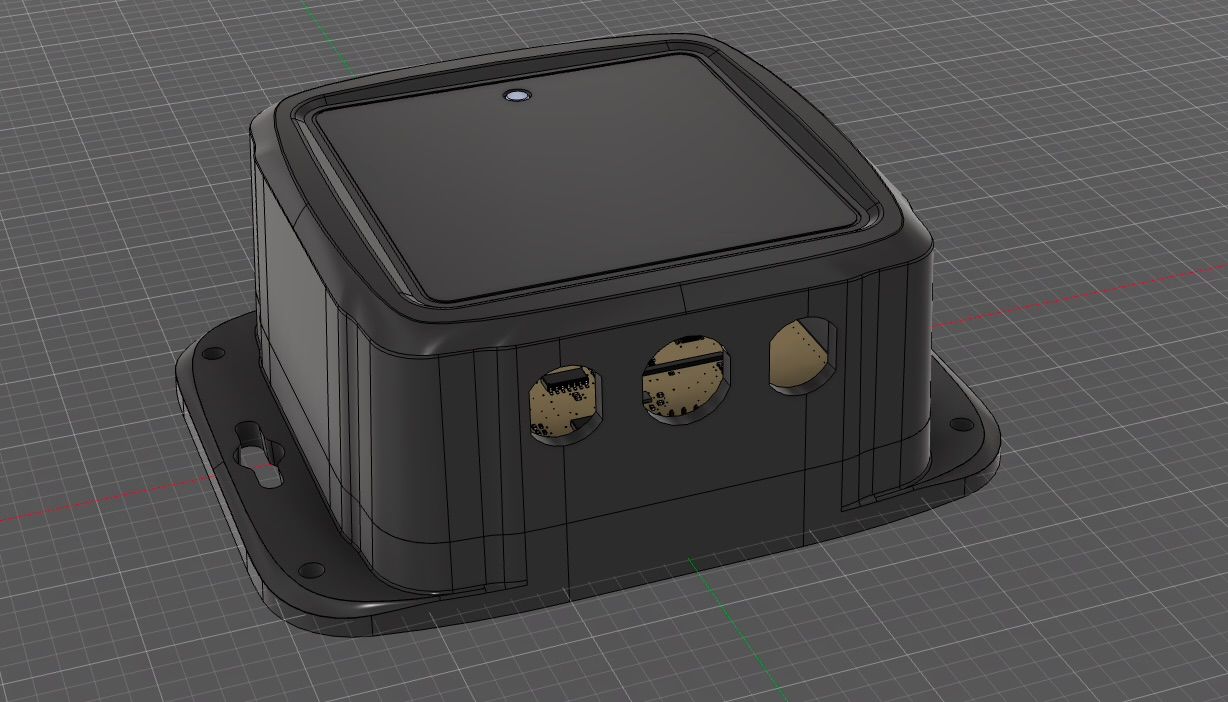

The solution also involved purpose-built wire harnessing to simplify field installation and custom enclosure sourcing and modification. The device streams operational data to a cloud backend via a cellular data pipeline where it is processed, stored, and visualized in real time.

Architecture (High Level)

Sensors → Analog Front-End → MCU → Cellular Modem → AWS → TimescaleDB → Web Dashboard + Mobile App

My Responsibilities

- Hardware architecture and schematic design

- PCB layout (mixed-signal, multi-channel analog)

- Enclosure design and mechanical integration

- Firmware and device bring-up

- Manufacturing coordination and field deployment support

- AWS infrastructure design and operations

- Backend APIs and data ingestion pipelines

- Frontend dashboard architecture (with frontend engineer)

- Mobile app architecture (Expo / React Native)

Impact

- Thousands of devices deployed across enterprise customers

- Enabled continuous HVAC performance monitoring and diagnostics

- Reduced on-site service requirements

- Contributed to ~$10M peak company valuation

- Platform adopted by large commercial clients as a core monitoring tool

Confidentiality Note

Source code and schematics are not public due to IP and customer agreements.

Visuals

Cellular HVAC Monitoring Device